El Tornillo Motor Injection Machine

HDPE

MELTING

INJECTION

PS

LDPE

PP

El Tornillo Motor Injection Machine

HDPE

MELTING

INJECTION

PS

LDPE

PP

Difficulty:

Hard

Time Required:

3-4 weeks

Views:

444Creator:

el-tornillo-tallerCountry:

ColombiaEmail:

andresgrzn@gmail.comDownloads:

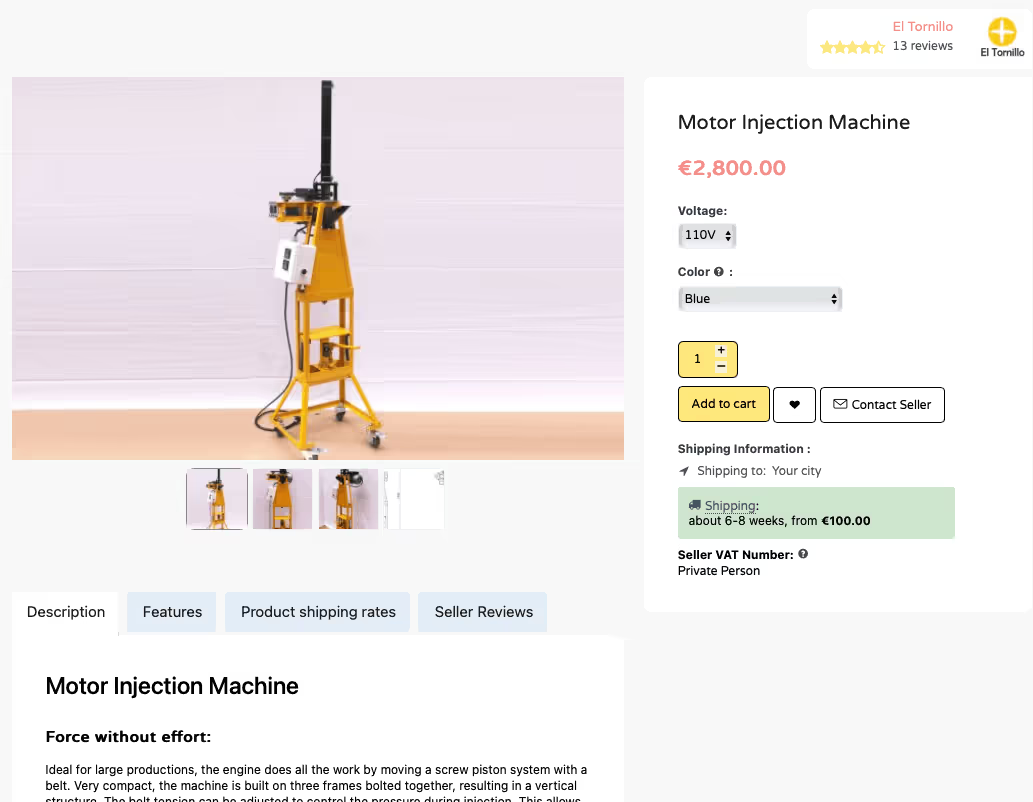

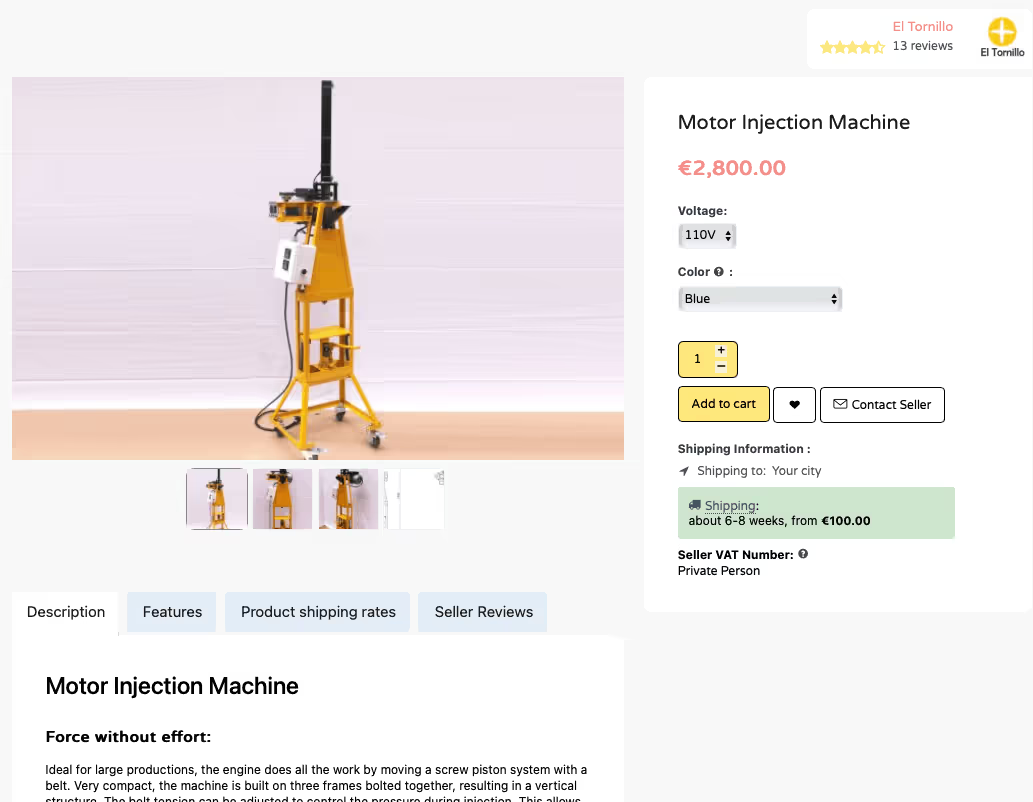

346This injection machine runs with a motor to save some labor and output more pressure to make more detailed products.

Browse Files

Table of Contents

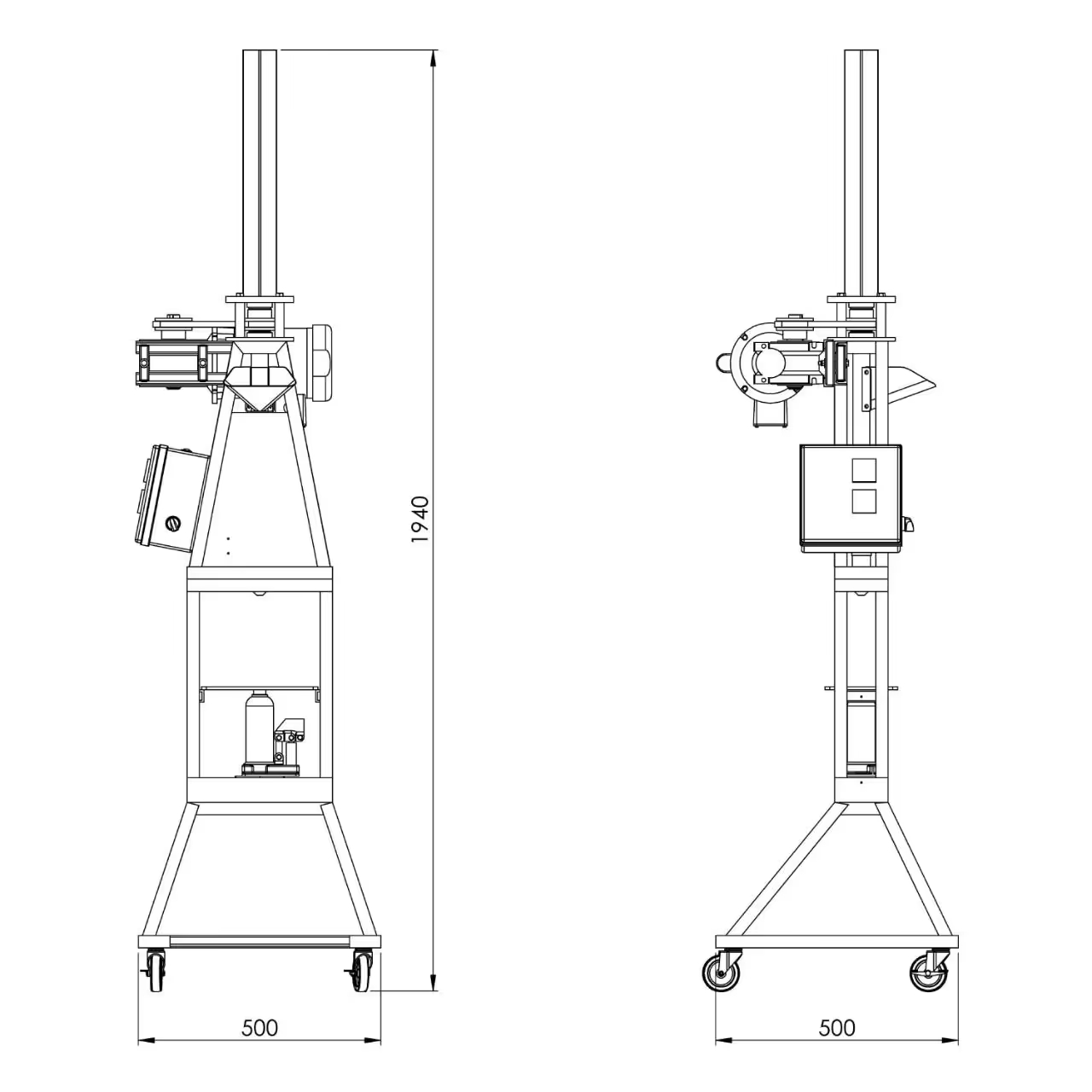

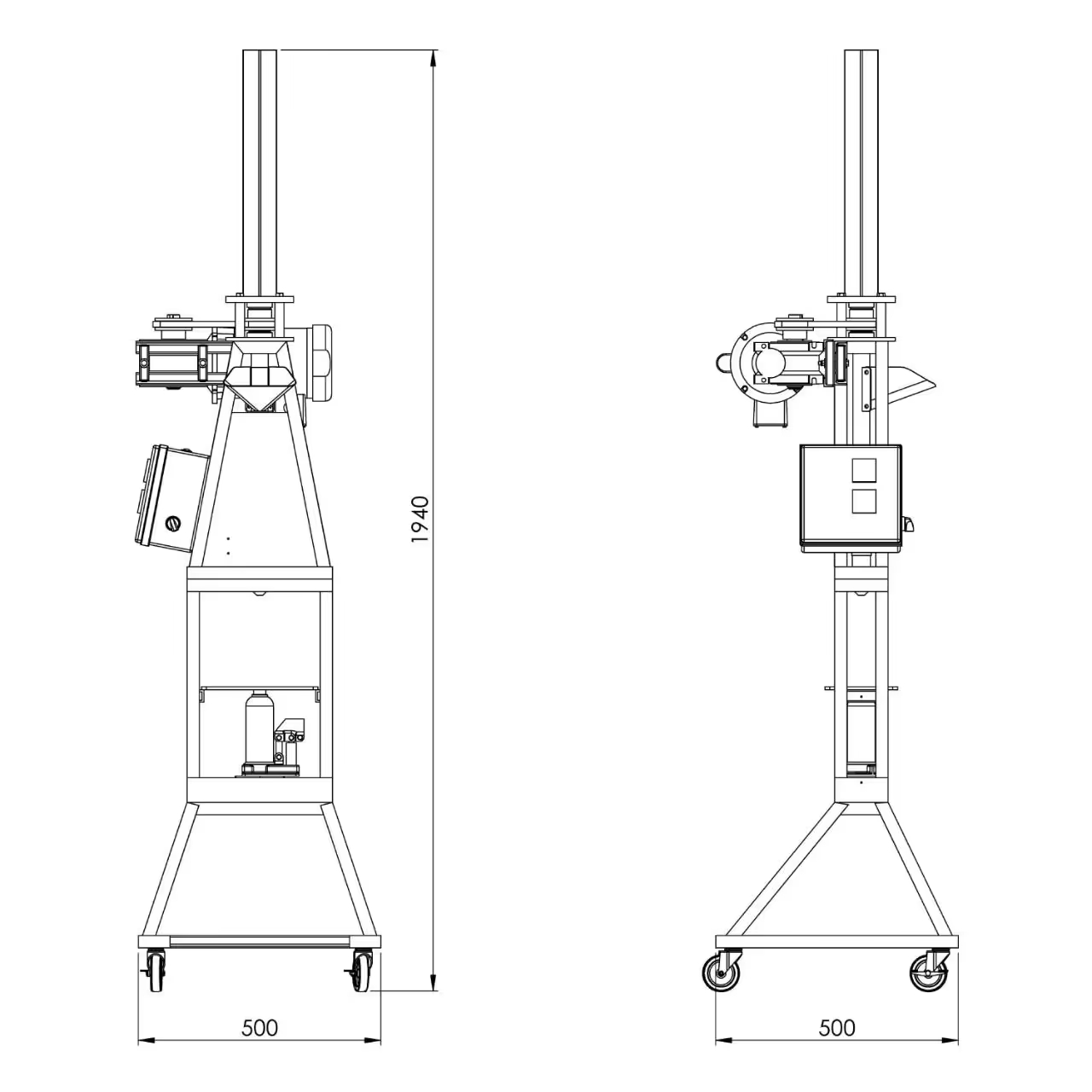

Machine design: Motor Injection Machine

Machine size: Heigth: 195CM; Wide: 50CM; Large: 50CM

Machine cost: In Colombia, Bill Of Material = COP$4,700,000

What makes your machine different to others: This machine has a motor that will apply the pressure (versus a hand powered lever on older versions). It can be considered an upgrade to [filtered] Basic Injection Machine, available on the academy.

Compatible with: This machine is suitable for injection moulds.

Type of plastic: PP, HDPE, LDPE, PS

To build this machine, you will need:

-- Turning (machining on a lathe) -- Milling (machining on a mill) -- General metalworking (cutting, drilling) -- Welding -- Advanced assembly work (require specific tools, measurement instruments and tolerances knowledge to align and assemble) -- General electrical work (wiring safety switch, temperature controllers…) -- Motor electrical work (wiring motor, contactor, overload protection…)

Watch this video to find out how to build this machine!

0:00 Before you start 3:09 Motor Injection Machine intro 3:36 Chapter I: Build the frame 7:12 Chapter II: Build the mould area 8:25 Chapter III: Build the piston system 14:39 Chapter IV: Build the heating barrel 17:51 Chapter V: Electrical wiring 18:56 Chapter VI: Connect the motor 20:10 Chapter VII: Assembly

Inject!

How to use the machine

Recommendations For this machine, you will need molds that have a connical nozzle connection or create an adapter to fit with you mold nozzle. This machine can create a lot of pressure so you will be able to inject products with very thin walls.

So this is how you make a Motor Injection Machine!

If you cannot replicate the machine or simply want to buy some of the other machines or moulds I create, make sure to visit my Bazar shop 🤑 !

This summary distills key requirements for constructing the injection machine, referencing timestamps from the instructional video.